Within the World of Vacuum-Based Electrical Pass-Throughs: A Detailed Guide

In the realm of advanced industries and development facilities, vacuum electrical feedthroughs play a key role in maintaining the delicate balance between the external environment and the controlled conditions within vacuum systems. These dedicated components are essential in applications ranging from scientific research to semiconductor manufacturing, where accurate electrical connections must be made without endangering the integrity of a vacuum environment. Understanding the mechanics and applications of vacuum feedthroughs reveals the intricate connection between electrical systems and vacuum technology.

These feedthroughs effectively facilitate the transfer of electrical signals in and out of a vacuum chamber, making it possible the operation of various equipment that relies on a vacuum environment. By providing a continuous interface, these components not only enhance the performance of vacuum systems but also ensure the durability and reliability of the sensitive equipment housed within. As industries continue to push the limits of technology, exploring the nuances and innovations surrounding vacuum electrical feedthroughs becomes progressively important.

Types of Vacuum Electrical Feedthroughs

Vacuum electrical feedthroughs come in various designs, every one designed to specific uses and contexts. A frequent variety is the ceramic type, which utilizes insulating ceramic materials to provide electrical separation while upholding a sealed vacuum. Such feedthroughs are commonly used in high-voltage cases due to their excellent dielectric characteristics and resistance to corrosion. Their durable construction and ability to resist extreme conditions make them a preferred choice in sectors such as the manufacturing of semiconductors and particle physics.

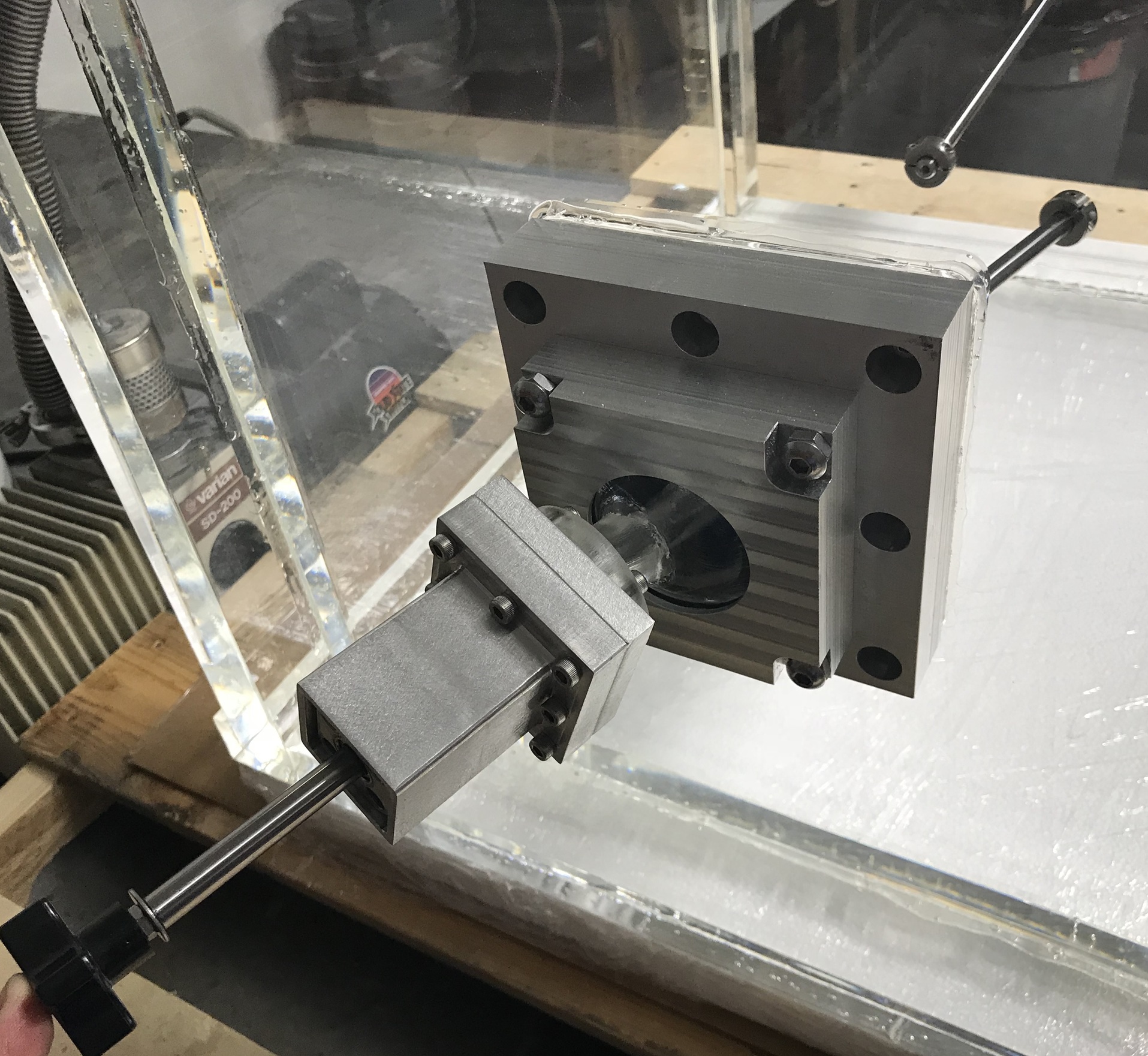

Another prevalent type is the metal model, often used for situations requiring grounding or signal transmission to move across a vacuum seal. These units typically consist of tubes made of metal with a sealed profile, which allows the transmission of electricity and signals while keeping the vacuum integrity. Their robustness and fitness to support elevated currents make them perfect for vacuum environments that require heavy equipment or scientific experiments.

Lastly, there are custom feedthroughs engineered for particular purposes, such as thermocouple feedthroughs, used for measuring temperature inside a vacuum space. These units are equipped with integrated sensors that can offer precise temperature data while simultaneously ensuring that the vacuum seal is kept secure. The diversity in vacuum feedthrough designs allows for a broad spectrum of uses across multiple industries, allowing that each system can operate optimally in their respective conditions.

Uses in Industry

Vacuums electric feedthroughs are commonly utilized in various industrial applications, particularly in settings that require high vacuum states. One notable field of application is in the semiconductor manufacturing sector, where these feedthroughs are necessary for connecting electrical components to devices that functions under vacuum conditions. They allow the transfer of electrical currents and power while preserving the integrity of the vacuum environment, crucial for processes such as photolithography and ion implantation processes.

Another significant application is found in the field of experimental and research laboratories. Vacuum feedthroughs are utilized in devices such as particle accelerators and vacuum chambers, where precise control of electrical signals is necessary for experimental accuracy. These feedthroughs ensure that currents can be effectively transmitted into the vacuum environment without disrupting the vacuum integrity, enabling a variety of scientific advancements.

Furthermore, vacuum electrical feedthroughs play a crucial role in the aerospace and defense fields. In space systems, they are used to connect sensors, instruments, and communication devices in satellite and spacecraft uses. The ability to transmit power and data in elevated vacuum conditions is essential for the performance and reliability of these systems, making vacuum feedthroughs an integral component in ensuring successful missions and activities in outer space.

Engineering Factors and Issues

When designing vacuum electrical feedthroughs, one of the key considerations is the choice of materials. The feedthrough must be fabricated from materials that can withstand the harsh conditions of a vacuum environment while ensuring electrical conductivity and insulation properties. Typical materials include ceramics and metals, which provide different benefits and drawbacks in terms of thermal expansion, durability, and electrical performance. Engineers must meticulously evaluate the compatibility of these materials with the specific application to ensure long-term dependability.

Another crucial challenge lies in achieving optimal sealing integrity. Vacuum feedthroughs must prevent any gas or moisture intrusion while facilitating electrical connections. This requires accurate engineering to ensure that seals are not only efficient but also resilient against thermal cycling and mechanical stresses. Various sealing methods, such as plastic, rubber, or metal seals, can be used, each presenting its own set of benefits and possible pitfalls. The selection of sealing method can considerably influence the overall performance and lifespan of the feedthrough.

Lastly, the overall incorporation of vacuum electrical feedthroughs into current systems poses unique challenges. Compatibility with various mounting and alignment configurations is essential to ensure ease of installation and maintenance. Additionally, feedthroughs must be designed to handle defined electrical loads without overheating or causing arcing within the vacuum enclosure. Balancing these design factors with cost-effectiveness and manufacturability is important for delivering robust feedthrough solutions that meet the needs of sophisticated vacuum applications.